An ISO 9001:2008 Certified Company

Hydraulic Plate Rolling Machine Manufacturer Supplier from Maharashtra

Product Details:

- Production Capacity Up to 6 meters/min rolling speed

- Operating Temperature -10C to +45C

- Noise Level <75 dB

- Motor Power 7.5 - 15 HP

- Frame Type Heavy-duty welded steel frame

- Cooling System Air cooled motor and hydraulic oil cooling unit

- Control System Panel mounted digital/electrical controls

- Click to View more

X

Hydraulic Plate Rolling Machine Manufacturer Supplier from Maharashtra Price And Quantity

- 1 Piece

Hydraulic Plate Rolling Machine Manufacturer Supplier from Maharashtra Product Specifications

- Hydraulic Plate Bending

- 50 Hz

- Hydraulic Plate Rolling Machine

- Panel controls, manual adjustments

- Sturdy steel frame, precision hardened rollers, safety interlock, emergency stop

- HPRM-3080

- 415 V AC

- Multicolor (Customizable as per order)

- Hydraulic motor drive

- Centralized grease/oil lubrication

- Approx. 4200 kg

- Electric

- 3 Phase, 415V

- Rolling/bending metal plates for fabrication, shipbuilding, construction, machinery, and infrastructure

- 0.2 mm

- Semi-Automatic

- Painted / Powder Coated

- Air cooled motor and hydraulic oil cooling unit

- 3100 x 1250 x 1500 mm (standard)

- Panel mounted digital/electrical controls

- Heavy-duty welded steel frame

- <75 dB

- Hydraulic mechanism with precision rolling

- 7.5 - 15 HP

- -10C to +45C

- Up to 6 meters/min rolling speed

- Hydraulic (adjustable as per requirement)

- 10-15 kW

Hydraulic Plate Rolling Machine Manufacturer Supplier from Maharashtra Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- CE & ISO

Product Description

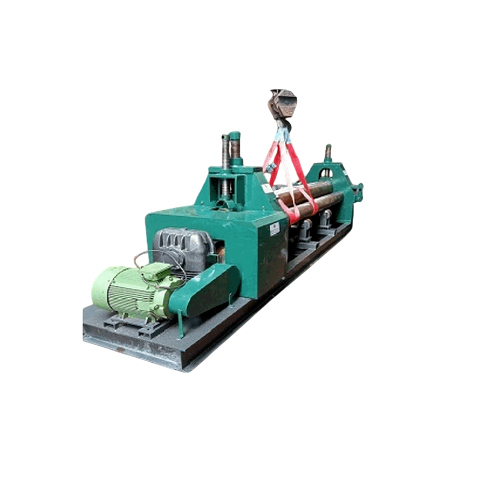

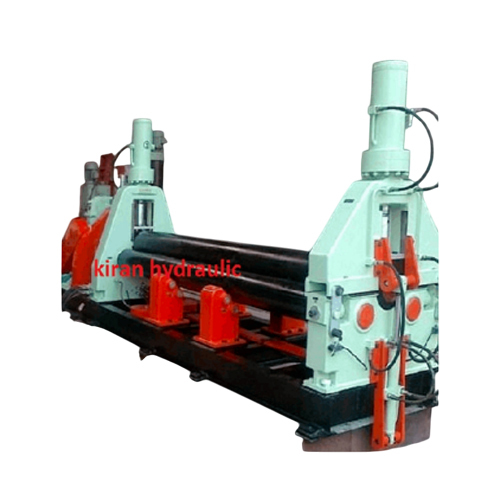

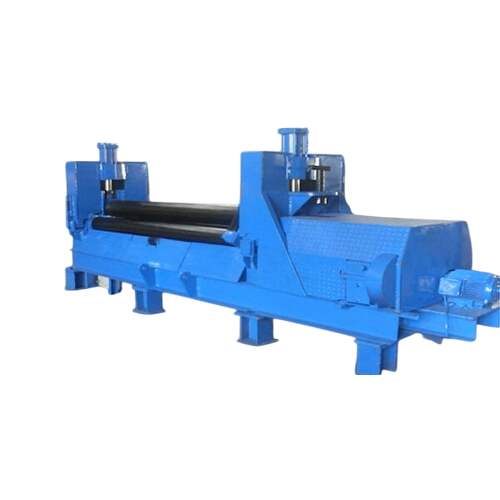

We Offer a Wide Array of Excellent Quality 3 Roll Hydraulic Plate Bending Machine. Manufacturer and Supplier of Hydraulic Plate Bending Machine From Mumbai, India.

1. Performance

2. Reliability

3. Quality

4. Technology

5. Experience

6. Service

Precision Hydraulic Technology

The HPRM-3080 utilizes advanced hydraulic mechanisms coupled with hardened alloy steel rollers to deliver consistent, high-accuracy bending. Operators benefit from adjustable pressure settings, digital control panels, and centralized lubrication, making complex rolling tasks both manageable and reliable, even on large-scale metal plates.

Safety and Operational Ease

Incorporating overload protection, emergency stop systems, and comprehensive safety guards, our machine ensures operator safety. Control is managed via a convenient foot pedal and manual lever, supported by panel-mounted digital controls for seamless operation, reducing fatigue and enhancing workflow efficiency.

Versatile Industrial Applications

Built for industries like fabrication, shipbuilding, and construction, the HPRM-3080 supports fabrication of varied metal plates, up to 6 meters/min rolling speed. Its customizable color, heavy-duty welded frame, and semi-automatic operation accommodate diverse client specifications and demanding workloads.

FAQ's of Hydraulic Plate Rolling Machine Manufacturer Supplier from Maharashtra:

Q: How does the Hydraulic Plate Rolling Machine ensure precise bending of metal plates?

A: This machine features three pyramid-type hardened and ground alloy steel rollers, hydraulic pressure adjustment, and precision controls, achieving plate bending accuracy to 0.2 mm, even for maximum thickness and width specifications.Q: What is the process to operate the plate rolling machine safely and efficiently?

A: Operation involves positioning the plate, activating the hydraulic system via panel-mounted digital controls, and using either the foot pedal or manual lever. Safety is enhanced by integrated overload protection, emergency stop buttons, and safety guards around the working area.Q: When should installation services be requested for this machine?

A: Installation services are available upon request and recommended at the time of purchase to ensure optimal setup, especially for large-scale applications or new facilities unfamiliar with hydraulic plate rolling technology.Q: Where can this plate rolling machine be used most efficiently?

A: It is ideal for metal fabrication units, shipbuilding, machinery manufacturing, construction, and infrastructure projects requiring precise and efficient plate bending of up to 20 mm thick and 3000 mm wide steel plates.Q: What are the benefits of using this hydraulic plate rolling machine over traditional models?

A: Users gain higher productivity, enhanced safety, semi-automatic operation, and improved bending accuracy. Features like centralized lubrication, air-cooled motor, and digital controls reduce downtime and maintenance requirements.Q: How do I customize the machine's color or specifications to fit my requirements?

A: Custom color options and specifications can be selected at the time of order, ensuring the machine aligns with your facility's needs and branding, while tailored features are accommodated within manufacturing limits.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email