An ISO 9001:2008 Certified Company

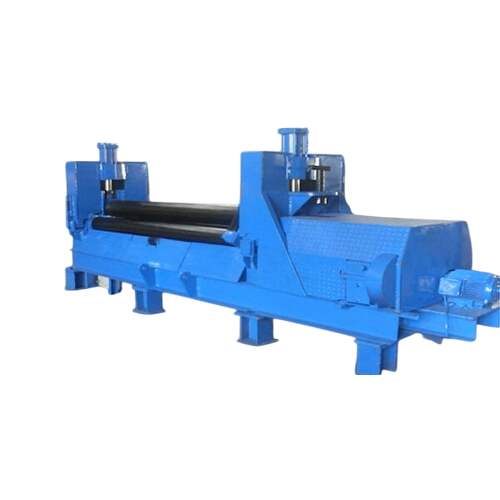

2000MM HYDRAULIC PLATE ROLLING MACHINE

1150000 INR/Number

Product Details:

- Operating Temperature 5C to 45C

- Frame Type Fabricated Steel

- Frequency 50 Hz

- Production Capacity Up to 8T per shift

- Motor Power 7.5 kW

- Drive Hydraulic Motor

- Connectivity Options Manual / PLC panel

- Click to View more

X

2000MM HYDRAULIC PLATE ROLLING MACHINE Price And Quantity

- 1150000 INR/Number

- 1 Number

- 300 mm (for 8mm plate)

- Powder Coating with Anti-rust Primer

- MCB, Fuses

- Hydraulic

- 8 mm (MS)

- 2000 mm

- Push Button / Optional HMI

- 195 mm (approx.)

- 38 Liters

- Analog / Digital (on request)

- 220 mm (approx.)

- Fixed with leveling pads

- Mild Steel, Stainless Steel, Aluminum sheets

- EN8 Hardened Steel

- Emergency stop, overload protection

- Manual & Hydraulic

- 90% RH

- > 50 HRC

- 3 (Pyramid Type)

2000MM HYDRAULIC PLATE ROLLING MACHINE Product Specifications

- Industrial fabrication, sheet rolling, press brake operations

- Up to 8T per shift

- 7.5 kW (approx)

- Hydraulic Plate Rolling Machine

- Plate Rolling

- Manual / PLC panel

- Hydraulic Motor

- 7.5 kW

- 3200

- Fabricated Steel

- 5C to 45C

- Approx. 3500 x 1300 x 1200 mm

- 50 Hz

- Semi-Automatic

- Hydraulic Bending

- Paint Coated

- 415 V AC

- Heavy-duty frame, hardened rolls, safety interlocks

- < 75 dB

- Centralized lubrication system

- 7.5 kW

- Air / Oil cooled

- PLC / Manual controls

- Hydraulic Operated

- 0.3 mm

- Electric

- Gray

- HPR-2000

- 300 mm (for 8mm plate)

- Powder Coating with Anti-rust Primer

- MCB, Fuses

- Hydraulic

- 8 mm (MS)

- 2000 mm

- Push Button / Optional HMI

- 195 mm (approx.)

- 38 Liters

- Analog / Digital (on request)

- 220 mm (approx.)

- Fixed with leveling pads

- Mild Steel, Stainless Steel, Aluminum sheets

- EN8 Hardened Steel

- Emergency stop, overload protection

- Manual & Hydraulic

- 90% RH

- > 50 HRC

- 3 (Pyramid Type)

2000MM HYDRAULIC PLATE ROLLING MACHINE Trade Information

- MUMBAI PORT

- Telegraphic Transfer (T/T)

- 40 Days

- If order is confirmed we will reimburse the sample cost

- WOODEN BOX

- Asia

- All India

- ISO9001:2015

Product Description

Make

Model KHPR 2000

Machine Size 2000mm Width X 32mm MS Plate

Top Roll Dia 320mm

Bottom RollDia 280mm

MotorDetails

Motor 30HP RPM 960Horizontal Foot Mounted IE2 IP 55

HydraulicMotor 10HP RPM 1440

Make Motor SIEMENS HINDUSTAN ABB

Gear Box Details

Gear Box Type WormReduction

Make Premium

Centre Height 8 INCH

Top Roll Attached in two cylindered 100 toneach.

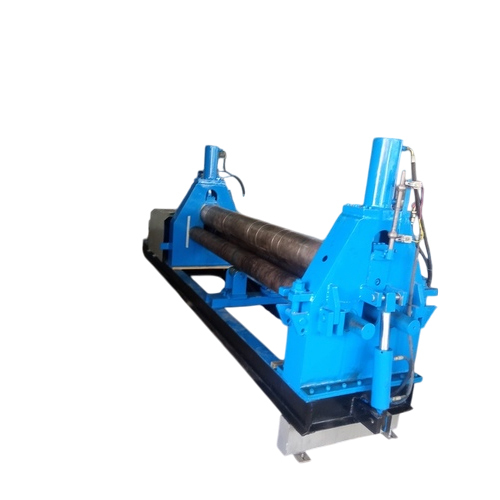

Precision Hydraulic Operation

Our plate rolling machine employs hydraulic motors and controls for consistent pressure during operation. Both manual and automatic roll parallelism adjustments are available, ensuring even and accurate bending of sheets. The bottom roll is adjusted hydraulically, simplifying setup and enhancing productivity for various fabrication projects.

Durable EN8 Hardened Steel Rollers

The rollers, manufactured from EN8 hardened steel, offer a surface hardness above 50 HRC. This ensures minimal wear and enables reliable long-term use when processing mild steel, stainless steel, or aluminum plates. The system accommodates a minimum rolling diameter of 300 mm for 8 mm thick plates, delivering versatility for different fabrication requirements.

Safety and Control Features

Operator safety is prioritized with advanced protections including emergency stop, overload circuits, and electrical safeguards like MCBs and fuses. The machine offers a robust fabricated steel frame, powder-coated for anti-rust performance, and efficient centralized lubrication. Control panels are available in manual push-button or optional digital HMI, backed by PLC integration for smarter operations.

FAQ's of 2000MM HYDRAULIC PLATE ROLLING MACHINE:

Q: How does the hydraulic plate rolling machine improve fabrication accuracy?

A: The HPR-2000 uses hydraulic operation to control bottom roll adjustment and pressure application, ensuring uniform bending. Combined with roll parallelism adjustment-manual and hydraulic-accuracy is maintained within 0.3 mm for consistent results across varied sheet thicknesses.Q: What materials can the 2000MM hydraulic plate rolling machine process?

A: This machine is suitable for rolling mild steel, stainless steel, and aluminum sheets. Its EN8 hardened steel rollers, high roll hardness, and robust frame allow for efficient processing of a range of sheet metals up to 8 mm thick and 2000 mm wide.Q: When should I use the emergency stop or overload protection features?

A: Emergency stop and overload protection should be activated immediately when there is any unsafe operating condition, unexpected machine movement, or electrical disturbance. These features are designed to protect both operators and the machine from damage or accidents during operation.Q: Where is the machine best utilized within industrial settings?

A: The HPR-2000 is ideally deployed in workshops, fabrication plants, and metalworking facilities that require precise sheet rolling, plate forming, or press brake operations. Its fixed base with leveling pads ensures stability and safety during heavy-duty industrial use.Q: What is the typical process for setting up and operating this plate rolling machine?

A: Set-up involves positioning the plate, selecting desired roll adjustments, and calibrating the control panel (analog, digital, or HMI). Hydraulic adjustment makes bottom roll setting straightforward, while centralized lubrication and parallelism controls streamline regular operation and maintenance.Q: How does the machine's surface treatment and painting enhance longevity?

A: The powder coating with anti-rust primer provides superior protection against corrosion, wear, and environmental humidity. This ensures the machine's durability and reliable performance even under continuous industrial usage.Q: What are the key benefits of choosing this hydraulic plate rolling machine?

A: Key benefits include high production capacity (up to 8 tons per shift), reliable roll accuracy, robust safety features, flexible control options, and excellent durability thanks to hardened rolls and advanced surface treatments-all contributing to cost-efficient, quality sheet processing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email