An ISO 9001:2008 Certified Company

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from India

Product Details:

- Connectivity Options Optional HMI & Remote Control

- Lubricating System Centralized Automatic Lubrication

- Frequency 50-60 Hz

- Frame Type Heavy-duty Welded Steel Frame

- Cooling System Oil Cooling Unit

- Power Rating Standard/Customized as per requirement

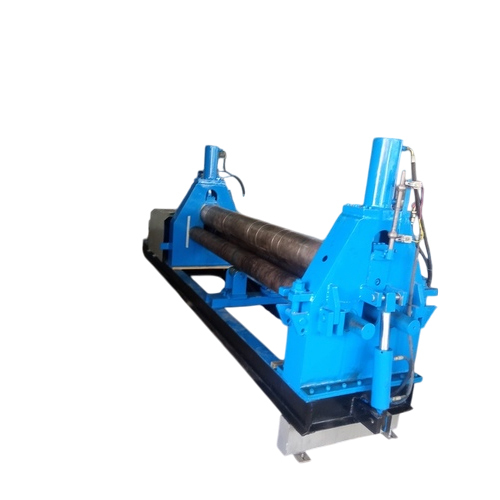

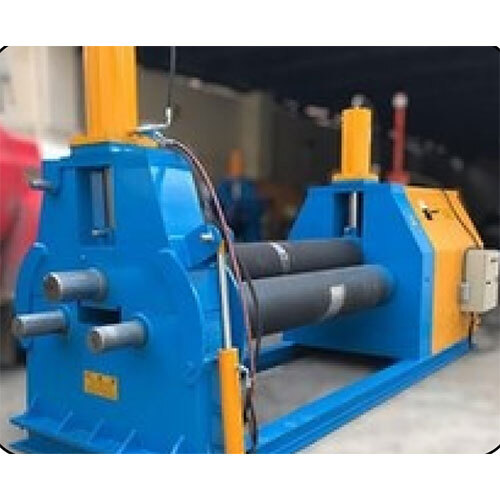

- Machine Type Plate Bending Roll

- Click to View more

X

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from India Price And Quantity

- 1 Piece

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from India Product Specifications

- Hydraulic Motor Drive

- 7.5 kW - 30 kW

- <75 dB

- Efficient, Rigid Construction, Easy Operation, User Friendly Controls

- 7.5 kW - 30 kW

- PLC / Manual

- Plate Rolling Machine

- Hydraulic

- Custom as per order

- Up to 320 bar

- Automatic / Semi-Automatic

- Rolling Mild Steel, Stainless Steel, Aluminium Plates

- 415 V, 3-Phase AC

- Up to 20 Ton/day

- Plate Bending Roll

- Paint Coated

- 3500 - 11000 kg (Model Dependent)

- 0.2 mm

- 0C to 45C

- Blue / Custom Options

- Hydraulic Cylinder Operated

- Centralized Automatic Lubrication

- 50-60 Hz

- Optional HMI & Remote Control

- Standard/Customized as per requirement

- Variable as per model (e.g., 3500mm x 1200mm x 1500mm)

- Heavy-duty Welded Steel Frame

- Oil Cooling Unit

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from India Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Africa, Asia, Central America

- All India

- CE & ISO

Product Description

We Offer a Wide Array of Excellent Quality 3 Roll Hydraulic Plate Bending Machine. Manufacturer and Supplier of Hydraulic Plate Bending Machine From Mumbai, India.

1. Performance

2. Reliability

3. Quality

4. Technology

5. Experience

6. Service

Precision Hydraulic Plate Rolling Technology

Utilizing heavy-duty construction and advanced hydraulic systems, our plate rolling machines ensure accurate results with a roll accuracy of 0.2 mm. The robust frame and powered control system contribute to reliable bending operations for diverse metal applications, adapting seamlessly to project specifications.

Comprehensive Safety and User-Friendly Controls

Operators benefit from dedicated safety features such as emergency stop buttons and overload protection, alongside intuitive digital readouts and foot switches. The centralized automatic lubrication system, oil cooling unit, and easy-to-navigate controls make these machines practical and efficient in heavy production environments.

Flexible Configurations and Global Support

From OEM service to optional accessories like cone bending attachments, NC/CNC controls, and remote operation, our hydraulic plate rolling machines can be tailored to any industrial demand. We offer on-site installation, commissioning, and readily available spare parts to keep your production running smoothly worldwide.

FAQ's of Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from India:

Q: How can I select the right hydraulic plate rolling machine model for my application?

A: The ideal model depends on your plate dimensions, material type, required thickness, and production volume. We offer machines with roll diameters from 200 mm to 500 mm and plate widths ranging from 1500 mm to 3200 mm. Our experts can help you match your specifications for optimum performance.Q: What safety features are integrated into your plate rolling machines?

A: Our machines include an emergency stop button, overload protection, and robust construction. These features, combined with heavy-duty roller bearings and a secure frame, ensure operator safety during all rolling operations.Q: Where do you offer after-sales support and spare parts?

A: We provide on-site installation, commissioning, and readily available spare parts. Our support network extends across Gulf countries, Africa, Europe, and South-East Asia, ensuring prompt assistance wherever your operations are based.Q: What is the process for installing and commissioning the machine?

A: On-site installation and commissioning are managed by our technical team. We ensure that the machine is correctly set up, configured according to your requirements, and rigorously tested for safe and efficient operation before production begins.Q: What are the available control systems and operating types?

A: Our machines offer both PLC (automatic) and manual controls, so you can choose automatic or semi-automatic operation. Optional HMI and remote control connectivity allow integration with modern plant systems for user-friendly operation.Q: What are the main benefits of hydraulic plate rolling technology in your machines?

A: Hydraulic operation delivers consistent pressure, efficient material handling, and reduced manual effort. It ensures uniform bending quality, operational safety, and adaptability for a wide range of metals and thicknesses, resulting in reliable production output.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email