An ISO 9001:2008 Certified Company

Pyramid Type Hydraulic Plate Bending Machine Supplier from Maharashtra

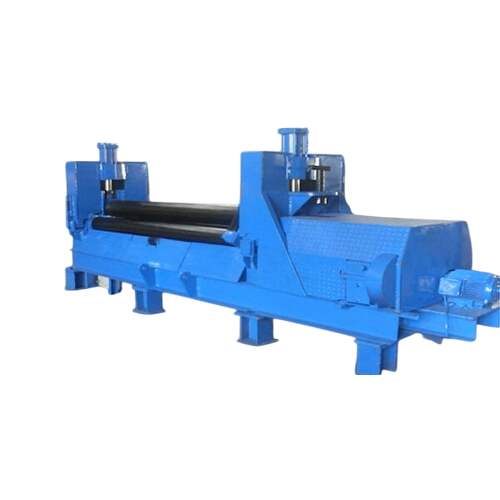

Product Details:

- Drive Hydraulic Motor Driven Rollers

- Machine Type Pyramid Hydraulic Bending Machine

- Model No PYR-120, PYR-150, PYR-200 (Example Models)

- Motor Power As per Model (7.5 kW up to 15 kW)

- Accuracy 0.3 mm

- Noise Level Below 80 dB

- Production Capacity Up to 10 Sheets/Hour

- Click to View more

X

Pyramid Type Hydraulic Plate Bending Machine Supplier from Maharashtra Price And Quantity

- 1 Piece

Pyramid Type Hydraulic Plate Bending Machine Supplier from Maharashtra Product Specifications

- Paint Coated

- Hydraulic (Variable Up to 200 Tons Depending on Model)

- 10 HP to 20 HP Depending on Model

- Electric

- Bending and Rolling Steel Plates for Industrial Fabrication, Construction, Automobile, and Heavy Engineering

- Hydraulic Bending Technology

- Varies as per Model (e.g., 3500 x 1600 x 1600 mm)

- Oil Cooled Hydraulic System

- Heavy Duty Structure, Easy Operation, Precision Guideways, High Efficiency

- Robust Welded Steel Frame

- 415 V (Three Phase, 50 Hz)

- Centralized Lubrication

- 7.5 kW to 15 kW (as per Model)

- Blue & White

- 50 Hz

- Pyramid Type Plate Bending Machine

- Hydraulic Control with Electrical Panel

- Semi-Automatic

- Up to 10 Sheets/Hour

- 5C to 50C

- Below 80 dB

- 0.3 mm

- 3300 kg (approx., depends on model)

- As per Model (7.5 kW up to 15 kW)

- Hydraulic Motor Driven Rollers

- PYR-120, PYR-150, PYR-200 (Example Models)

- Pyramid Hydraulic Bending Machine

Pyramid Type Hydraulic Plate Bending Machine Supplier from Maharashtra Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- South America, Eastern Europe, Western Europe, Central America, Middle East, Asia, North America, Australia, Africa

- All India

- CE & ISO

Product Description

We Offer a Wide Array of Excellent Quality 3 Roll Hydraulic Plate Bending Machine. Manufacturer and Supplier of Hydraulic Plate Bending Machine From Mumbai, India.

1. Performance

2. Reliability

3. Quality

4. Technology

5. Experience

6. Service

Precision and Flexibility in Plate Bending

Our plate bending machines offer powerful hydraulic technology with variable pressure up to 200 tons. The adjustable rollers, available in manual and hydraulic options, ensure precise results for diverse sheet sizes. With maximum bending width up to 2500 mm and thickness up to 20 mm, users can handle a range of fabrication tasks, from construction components to industrial frameworks.

Built for Safety and Reliability

Every machine is equipped with an emergency stop switch, overload protection, and adheres to Indian industrial safety standards. A heavy-duty welded steel frame, low noise levels (below 80 dB), and efficient cooling and lubrication systems guarantee safe, stable, and reliable operation in demanding environments.

Comprehensive Service and Support

We provide on-site installation and hands-on training ensuring smooth integration and optimal machine performance. Our support team assists with machine setup and maintenance, enabling customers to maximize productivity and minimize downtime. All machines come with a digital display system for real-time monitoring.

FAQ's of Pyramid Type Hydraulic Plate Bending Machine Supplier from Maharashtra:

Q: How does the hydraulic plate bending machine ensure accurate bending results?

A: The machine features precision guideways, digital position display, and hydraulic control systems, allowing operators to achieve up to 0.3 mm accuracy during plate bending. Both manual and hydraulic roll adjustments offer fine-tuned control over bending width and thickness.Q: What is the process for installing and starting up the Pyramid Hydraulic Bending Machine?

A: On-site installation and training are provided by our expert technicians. They will set up the machine according to your specifications, calibrate the controls, and train operators in safe and efficient usage, ensuring a smooth production start.Q: Where can these plate bending machines be used?

A: They are widely applied in industrial fabrication, construction, automobile manufacturing, and heavy engineering for bending and rolling steel plates. The robust build and versatility make them suitable for both small workshops and large-scale plants.Q: What safety features does the machine include to protect operators?

A: Safety is prioritized with features like an emergency stop switch, overload protection, vibration-controlled base, centralized lubrication, and full compliance with Indian industrial safety standards-all designed to minimize risks during operation.Q: What benefits does hydraulic technology bring to plate bending machines?

A: Hydraulic systems allow for variable pressure (up to 200 tons), efficient transmission of force, smooth and powerful bending, and easy control via electrical panels. This leads to improved power efficiency, faster cycle times, and superior bending quality.Q: How is maintenance handled for these machines?

A: Routine maintenance is simplified by the use of ISO VG-68 hydraulic oil, a centralized lubrication system, oil-cooled hydraulic units, and a robust frame that reduces wear. Support includes guidance on upkeep and fast troubleshooting through our service network.Q: What usage capacity and productivity can be expected?

A: Production rates can reach up to 10 sheets per hour, depending on machine configuration and sheet specifications. The machines are built for high efficiency, consistent output, and dependable operation in continuous industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email