An ISO 9001:2008 Certified Company

Hydraulic Cylinders Exporters Manufacturers Suppliers in Maharashtra

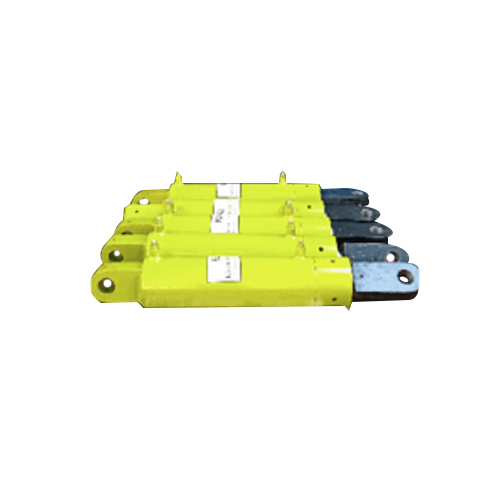

Product Details:

- Pressure Up to 350 bar

- Temperature -20C to +80C

- Capacity 1 ton to 100 ton

- Wall Thickness As per design/requirement

- Material Alloy Steel, Carbon Steel, Stainless Steel

- Structure Double Acting / Single Acting

- Power Hydraulic

- Click to View more

X

Hydraulic Cylinders Exporters Manufacturers Suppliers in Maharashtra Price And Quantity

- 1 Piece

Hydraulic Cylinders Exporters Manufacturers Suppliers in Maharashtra Product Specifications

- Hydraulic

- Polyurethane/Nitrile/Viton

- Standard / Customizable

- Alloy Steel, Carbon Steel, Stainless Steel

- Custom/As per specification

- -20C to +80C

- 1 ton to 100 ton

- Up to 6000 mm

- Hardened, Ground Steel

- Double Acting / Single Acting

- Up to 350 bar

- As per design/requirement

- 32 mm to 500 mm

Hydraulic Cylinders Exporters Manufacturers Suppliers in Maharashtra Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Australia, Africa

- All India

- CE & ISO

Product Description

Kiran Hydraulics Manufacturer, Supplier and Exporter of High Quality Hydraulic Power Pack and Hydraulic Cylinder From Mumbai, India. Advanced Machinery & High Quality Material. Perfect Engineering

Versatile Customization Options

Our hydraulic cylinders can be tailored to meet specific requirements, including bore sizes from 25 mm up to 800 mm, max strokes up to 6000 mm, and shaft diameters between 32 mm to 500 mm. Choose from welded, tie-rod, and telescopic types, with standard or custom port sizes, and a variety of mounting styles such as clevis, trunnion, and flange. Coating and surface treatments are available for enhanced corrosion resistance.

Designed for Demanding Industries

Engineered for vigorous applications, these cylinders are suited for use in industrial machinery, construction equipment, and complex material handling systems. Their robust construction supports pressures up to 350 bar and capacities up to 100 tons, with options to accommodate single or double-headed pistons. Multiple seal types, including polyurethane, nitrile, and Viton, ensure optimal performance in challenging environments.

Comprehensive Quality Assurance

Each cylinder undergoes stringent pressure testing up to 500 bar to guarantee durability and safety. Manufactured from high-grade alloy, carbon, or stainless steel, the products comply with rigorous standards. Special finishes such as hard chrome plating and powder coating, along with corrosion-resistant coatings, further enhance operational longevity and reliability for various industrial applications.

FAQ's of Hydraulic Cylinders Exporters Manufacturers Suppliers in Maharashtra:

Q: How are hydraulic cylinders from Maharashtra suppliers tested for quality and performance?

A: Every cylinder undergoes thorough pressure testing up to 500 bar to ensure it meets rigorous performance and safety standards. These processes verify the durability and integrity of the cylinders under high-pressure conditions.Q: What mounting styles are offered for these hydraulic cylinders and how do I select the right one?

A: Available mounting options include clevis, trunnion, flange, and foot mounting. The appropriate style depends on your machinery's configuration and operational requirements. Manufacturers and suppliers offer guidance based on your specific application.Q: When should I consider special surface treatments or coatings for hydraulic cylinders?

A: Special coatings such as hard chrome plating, zinc plating, and painted finishes are recommended when your cylinders will operate in corrosive or harsh environments. These treatments protect the components, thus extending service life and maintaining performance.Q: Where are these hydraulic cylinders commonly used?

A: These cylinders are extensively utilized in industrial machinery, material handling systems, and construction equipment. Their adaptability and customizable design allow integration into various sectors requiring high load bearing and precise hydraulic operations.Q: What are the benefits of using cylinders with single or double-headed pistons and various seal types?

A: Single and double-headed piston designs cater to different force requirements and stroke lengths. Multiple seal options such as polyurethane, nitrile, and Viton enhance compatibility with hydraulic oils, environmental conditions, and pressure demands, ensuring long-term leak-free operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email