An ISO 9001:2008 Certified Company

Hydraulic Cylinder Manufacturers in Maharashtra

Product Details:

- Wall Thickness As per design/specification

- Capacity Custom Built

- Temperature -10C to 80C

- Pressure Up to 700 Bar

- Material Alloy Steel / Mild Steel / Stainless Steel

- Structure Welded / Tie-rod

- Power Hydraulic

- Click to View more

X

Hydraulic Cylinder Manufacturers in Maharashtra Price And Quantity

- 1 Piece

- Epoxy / Polyurethane paint

- Available at both ends

- Clevis, Trunnion, Flange, Foot

- Hydraulic Oil / Other Media

- 1.5 times working pressure

- 50 mm to 1000 mm

- Double Acting / Single Acting

- Polished / Corrosion-Resistant

- Industrial Machinery, Construction Equipment, Material Handling, Agriculture

Hydraulic Cylinder Manufacturers in Maharashtra Product Specifications

- Up to 6000 mm

- 25 mm to 500 mm

- Welded / Tie-rod

- PU / NBR / VITON

- Up to 700 Bar

- Alloy Steel / Mild Steel / Stainless Steel

- Hard chrome plated

- Hydraulic

- Custom Built

- -10C to 80C

- Varies as per size

- Customized

- As per design/specification

- Epoxy / Polyurethane paint

- Available at both ends

- Clevis, Trunnion, Flange, Foot

- Hydraulic Oil / Other Media

- 1.5 times working pressure

- 50 mm to 1000 mm

- Double Acting / Single Acting

- Polished / Corrosion-Resistant

- Industrial Machinery, Construction Equipment, Material Handling, Agriculture

Hydraulic Cylinder Manufacturers in Maharashtra Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Central America, Asia, North America, South America, Eastern Europe, Western Europe, Middle East, Australia, Africa

- All India

- CE & ISO

Product Description

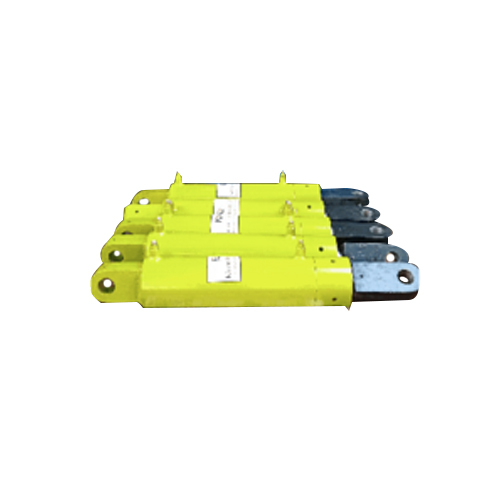

Kiran Hydraulics Manufacturer, Supplier and Exporter of High Quality Hydraulic Power Pack and Hydraulic Cylinder From Mumbai, India. Advanced Machinery & High Quality Material. Perfect Engineering

Diverse Mounting and Custom Engineering

Choose from various mounting styles-including clevis, trunnion, flange, and foot-to best suit your system's requirements. Each cylinder is custom engineered for your size, stroke, and specification needs, with bore diameters ranging from 50 mm to 1000 mm, and shaft diameters from 25 mm to 500 mm, ensuring compatibility with a broad range of applications.

Superior Finish and Long-Lasting Durability

Our cylinders benefit from a polished, corrosion-resistant surface finish and are protected with epoxy or polyurethane paint. For environments requiring resilience, hard chrome plated rods and high-grade alloy, mild, or stainless steel construction deliver extended service life and performance stability, even under heavy-duty conditions.

Reliable Performance Across Industries

Engineered with advanced seals (PU, NBR, VITON) and available in double and single acting types, our cylinders perform efficiently at pressures up to 700 Bar. Standard testing at 1.5 times working pressure ensures operational safety and reliability across industrial machinery, agricultural equipment, construction gear, and material handling systems.

FAQ's of Hydraulic Cylinder Manufacturers in Maharashtra:

Q: How do I select the appropriate mounting style for my hydraulic cylinder?

A: Selecting a mounting style (clevis, trunnion, flange, or foot) depends on your machinery's configuration and motion requirements. Consult our engineering team to determine the best fit for your application, ensuring optimal alignment, stability, and ease of maintenance.Q: What materials and surface finishes are available for your hydraulic cylinders?

A: We offer cylinders in alloy steel, mild steel, or stainless steel, tailored to the application's strength and corrosion resistance needs. Surface finishes include polished or corrosion-resistant coatings, complemented by epoxy or polyurethane paints for added protection in harsh environments.Q: When is cushioning at both ends necessary in hydraulic cylinders?

A: Cushioning at both ends is recommended for applications involving rapid or heavy movement to reduce impact at stroke limits. It enhances cylinder longevity, minimizes noise, and protects machinery from shock loads.Q: Where can these hydraulic cylinders be used, and what are typical applications?

A: Our cylinders are designed for use in industrial machinery, construction equipment, material handling systems, and agricultural machines. Their robust construction and high customization options make them ideal for diverse sectors requiring reliable linear actuation.Q: What is the process for ordering a custom-built hydraulic cylinder?

A: To order a custom cylinder, share your required dimensions, mounting type, operating pressure, application details, and material preferences with us. Our specialists will guide you through the design, manufacturing, and quality testing stages to ensure your product meets all specifications.Q: How do the seals and rod finishes contribute to cylinder performance?

A: We use premium seals (PU, NBR, VITON) to ensure leak-free operation across a wide temperature range and media. Hard chrome plated rods provide superior wear and corrosion resistance, extending service intervals and improving operational reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email