An ISO 9001:2008 Certified Company

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from Mambai India

Product Details:

- Frame Type Rigid Welded Steel Frame

- Motor Power 15 kW

- Lubricating System Centralized

- Cooling System Oil Cooled

- Noise Level < 80 dB

- Frequency 50 Hz

- Operating Temperature 5C to 50C

- Click to View more

X

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from Mambai India Price And Quantity

- 1 Piece

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from Mambai India Product Specifications

- Semi Automatic

- 0.25 mm

- Hydraulic Plate Rolling

- 415 V

- 5000 Kg

- Control Panel Interface

- Hydraulic Plating Rolling Technology

- PLC / Manual

- 10-20 kW (Based on Model)

- Heavy Duty Construction, Precise Bending, Easy Operation, Low Maintenance

- Industrial Blue & Yellow

- Hydraulic

- 15 HP

- Polished/Coated

- HPRM-4300

- Oil Cooled

- 150-300 Ton (Customizable)

- 15 kW

- Rigid Welded Steel Frame

- Sheet metal forming, Steel plate bending, Fabrication workshops

- Centralized

- Plate Rolling Machine

- 15 Rolls/Hour (Varies with material)

- 50 Hz

- < 80 dB

- Hydraulic Cylinder Drive

- 5C to 50C

- Custom; Standard: 4300 x 1600 x 1600 mm

Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from Mambai India Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Asia

- All India

- CE & ISO

Product Description

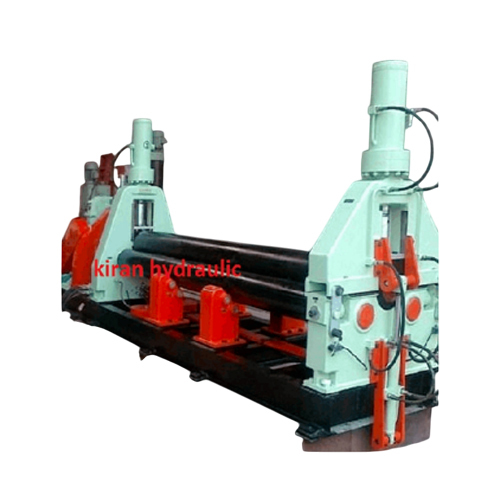

We Offer a Wide Array of Excellent Quality 3 Roll Hydraulic Plate Bending Machine. Manufacturer and Supplier of Hydraulic Plate Bending Machine From Mumbai, India.

1. Performance

2. Reliability

3. Quality

4. Technology

5. Experience

6. Service

Advanced Hydraulic Plate Rolling Technology

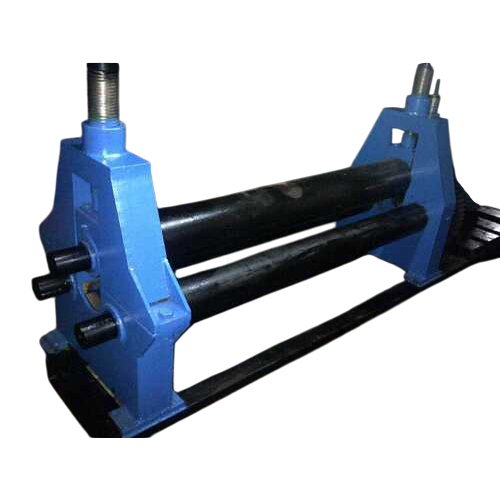

Utilizing hydraulic cylinder drive and a PLC/manual control system, the HPRM-4300 offers efficient plate bending for various thicknesses. Its centralized lubrication, oil-cooled system, and heavy-duty welded steel frame ensure long-term, hassle-free operation. The digital display guarantees precise roll adjustments, minimizing errors during forming.

Versatility and Customization

Available with either 3 or 4 rolls, this machine handles a wide range of materials and dimensions. Customizable pressure settings between 150-300 tons, optional pre-bending attachments, and robust backup rollers allow users to adapt the machine for unique fabrication needs. Standard dimensions and weight ensure seamless integration into most industrial settings.

Superior Safety and Support

Operator safety is prioritized with features such as emergency stop and overload protection. Whether shipped fully assembled or semi-knocked down (SKD), the manufacturer's on-site and remote service support helps with seamless installation and operation. The included caster wheels facilitate easy repositioning within workshops.

FAQ's of Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from Mambai India:

Q: How does the Hydraulic Plate Rolling Machine ensure precise bending operations?

A: Precision is achieved through hydraulically controlled roll adjustments with digital display interfaces. The machine maintains an accuracy of 0.25 mm, supported by hardened and ground alloy steel rolls, backup rollers for exact forming, and a PLC/manual control system.Q: What is the range of plate thickness and diameter this machine can process?

A: This model handles mild steel plates up to 20 mm thick and bends as small as 320 mm in diameter, depending on plate thickness and machine configuration. Roll diameter is 220 mm, supporting consistent performance across various materials.Q: When is on-site or remote technical support available for this machine?

A: The manufacturer offers both on-site and remote assistance for installation, maintenance, and troubleshooting. Support is available during initial setup and throughout the machine's operational life to ensure continuous productivity.Q: Where can the Hydraulic Plate Rolling Machine be shipped, and in what condition?

A: The machine is supplied from Mumbai, India, and can be shipped globally. It is delivered either fully assembled or in SKD (semi-knocked down) condition, depending on transportation requirements and customer preferences.Q: What is the standard process for operating and maintaining this plate rolling equipment?

A: Operation involves setting plate specifications on the control panel and adjusting rolls hydraulically. Regular maintenance includes monitoring hydraulic oil (68 grade), checking lubrication via the centralized system, and inspecting safety features such as emergency stop and overload protection.Q: How does the frame design and noise level benefit a fabrication shop environment?

A: A rigid welded steel frame ensures machine stability and durability during heavy-duty operation. The noise level remains below 80 dB, contributing to a safer and more comfortable working environment for operators.Q: What key benefits does this machine offer for sheet metal forming applications?

A: The machine delivers efficient, precise, and reliable bending of steel plates with rapid production capabilities-up to 15 rolls per hour. Its heavy-duty construction, low maintenance, and customizable features make it ideal for fabrication workshops seeking quality and productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email