An ISO 9001:2008 Certified Company

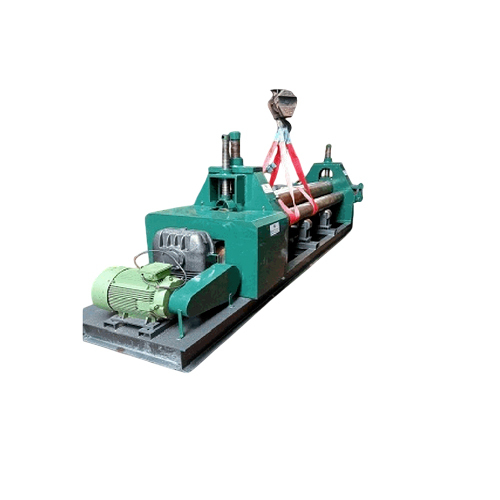

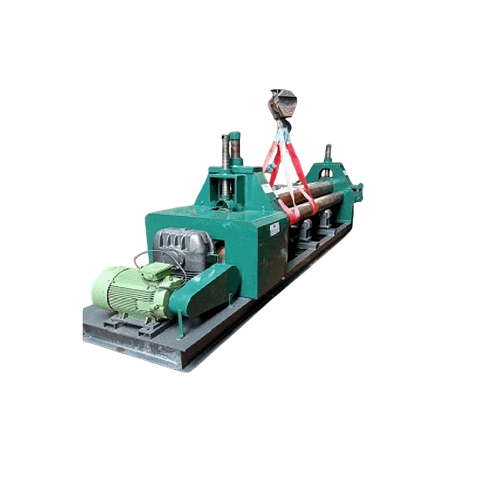

Excellent Quality Pyramid Type Plate Bending Machine

Product Details:

- Features High precision bending, rugged construction, easy to operate, heavy-duty gears, adjustable rear roll, safety features

- Control System Manual & Electrical controls

- Frequency 50 Hz

- Production Capacity 5-10 Ton/day

- Cooling System Natural Air Cooled

- Model No PYR-2500

- Lubricating System Manual Lubrication Points

- Click to View more

X

Excellent Quality Pyramid Type Plate Bending Machine Price And Quantity

- 1 Piece

Excellent Quality Pyramid Type Plate Bending Machine Product Specifications

- 2000 - 3500 kg

- Electric

- Manual Adjustment

- Pyramid Roll Bending

- 3 - 7.5 kW (depending on model)

- 5-10 Ton/day

- 50 Hz

- Manual & Electrical controls

- Pyramid Type Plate Bending Machine

- High precision bending, rugged construction, easy to operate, heavy-duty gears, adjustable rear roll, safety features

- Manual Lubrication Points

- PYR-2500

- Natural Air Cooled

- Blue & Yellow

- Gear Driven

- Semi-Automatic

- 5C - 45C

- Pyramid Plate Bending

- 415 V / 3 Phase

- Standard electrical connection

- 3 - 7.5 kW

- <75 dB

- Paint Coated

- 3-7.5 kW

- Heavy Duty Welded Steel Frame

- Varies with model (typically 2500mm x 950mm x 1200mm)

- 0.2 mm

- Sheet metal bending, duct fabrication, cylindrical/curved component manufacturing, fabrication workshops

Product Description

Excellent Quality Pyramid Type Plate Bending Machine

We Offer a Wide Array of Excellent Quality 3 Roll Hydraulic Plate Bending Machine. Manufacturer and Supplier of Hydraulic Plate Bending Machine From Mumbai, India.

1. Performance

2. Reliability

3. Quality

4. Technology

5. Experience

6. Service

Advanced Roll Bending Technology

The PYR-2500 plate bending machine employs pyramid roll bending technology with three precisely hardened and ground rolls for optimal durability and accuracy. This configuration allows users to efficiently form cylindrical and conical shapes, making the machine highly adaptable for various manufacturing tasks.

Precision Engineering and Sturdy Construction

Constructed with a heavy-duty welded steel frame, this bending machine offers excellent stability and long-lasting performance. Key features include high precision (0.2 mm), rugged gears, screw-type hand-wheel adjustment for rolls, and manual mechanical adjustment for consistent and reliable results, even with heavy plates.

User-Focused Design and Safety

Designed for ease of use, the PYR-2500 includes simple lever and push button controls, an emergency stop, and overload protection to ensure operator safety. Manual lubrication points and a supplied tool kit facilitate routine maintenance, while comprehensive documentation supports efficient operation.

FAQ's of Excellent Quality Pyramid Type Plate Bending Machine:

Q: How does the pyramid type plate bending machine operate?

A: The machine uses a three-roll, pyramid configuration where the main bottom rolls are electrically driven and the top roll is idle. Sheets are fed between the rolls, which are manually adjusted via screw and hand-wheel to achieve the desired bend. Lever and push button controls make operation straightforward.Q: What materials and thickness can this machine handle?

A: The PYR-2500 is capable of bending sheet metals up to 20 mm in thickness and a maximum width of 2500 mm. The roller material, made of hardened and ground alloy steel (50-55 HRC), enhances durability and allows the machine to handle various metals used in duct and component fabrication.Q: When is manual adjustment required during bending operations?

A: Manual mechanical adjustment is used to set the top roll position before and during bending to achieve the precise radius. Adjustments via the screw-type hand-wheel allow operators to customize settings according to the thickness and width of the workpiece.Q: Where can the PYR-2500 plate bending machine be used?

A: This machine is suitable for fabrication workshops, sheet metal processing industries, and manufacturing units. Its robust construction and versatility support applications such as ductwork, curved shell and cylindrical component production.Q: What is the typical process for bending plates with this machine?

A: Begin by adjusting the rolls to accommodate the plate's dimensions. Feed the metal sheet between the rolls, set the desired roll positions using the hand-wheel, then engage the drive. The rolls bend the plate to the specified diameter, allowing for precise cylindrical or conical shapes.Q: What are the key benefits of this plate bending machine?

A: Key advantages include high precision bending (0.2 mm), rugged construction for industrial durability, user-friendly controls, adjustable rear roll, and integrated safety features. These contribute to efficient and safe operation across a wide range of fabrication tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email