An ISO 9001:2008 Certified Company

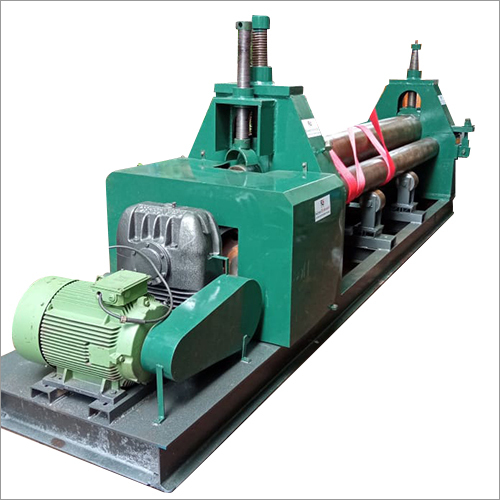

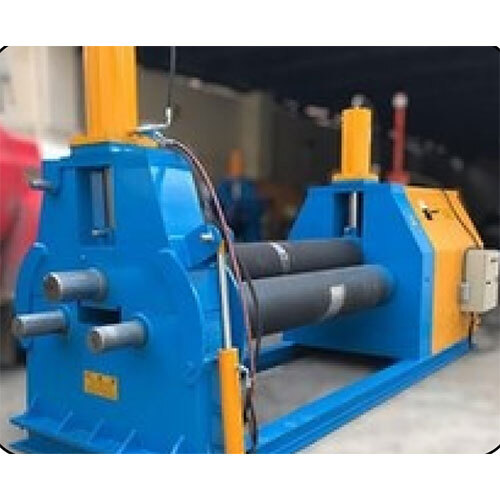

Plate Rolling Machine

950000 INR/Unit

Product Details:

X

Plate Rolling Machine Price And Quantity

- 950000 INR/Unit

- 1 , , Unit

Plate Rolling Machine Trade Information

- Mumbai

- Cash Advance (CA), Telegraphic Transfer (T/T)

- 2 , , Unit Per Month

- 45 Days

- If order is confirmed we will reimburse the sample cost

- wooden box

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- All India

- iso

Product Description

Kiran Hydraulics is manufacturing a premium quality plate rolling machine which is designed for rolling sheet metals. It is capable of rolling products into round, conical, and semi-round shapes. The said machine is widely utilized processing components for boiler equipment, tunnel supports, oil and gas rigs, heat exchangers, pressure vessels etc. In addition to this, this machine uses a tap roll and two side rolls for pressing the metal sheets. It is prepared using top grade stainless steel and advanced machineries. Our offered product is attributed with longer functional life, easy operations, seamless finishing, high performance efficiency and corrosion resistance.

Utilizations of Plate Rolling Machine:

1. Metal Manufacture: Plate rolling machines are broadly utilized in metal creation shops to curve and shape metal sheets for different purposes. They can make chambers, cones, and other bended shapes expected for tanks, lines, and strain vessels.

2. Tank and Strain Vessel Assembling: Plate rolling machines are critical in the development of capacity tanks, pressure vessels, and barrel shaped holders utilized in enterprises like oil and gas, synthetic handling, and water treatment.

3. Shipbuilding: Plate rolling machines are utilized to make bended segments of boat frames, as well as lines and cylinders for different marine applications.

4. Aeronautic trade: In aviation producing, plate rolling machines are utilized to shape bended parts like fuselage segments, motor nacelles, and primary components.

5. Structural and Development: Plate rolling machines can create bended metal parts utilized in building plans and development projects. This incorporates bended steel shafts, sections, and enhancing components.

6. Auto Industry: Plate rolling machines are utilized to shape metal parts for the auto business, for example, bended case parts, fumes lines, and bumpers.

7. Oil and Gas Industry: In the oil and gas area, plate rolling machines are utilized to make bended lines and cylinders utilized in pipelines, as well as parts for seaward designs.

8. Central air Frameworks: Warming, ventilation, and cooling (air conditioning) frameworks frequently require bended ventilation work and parts, which can be delivered utilizing plate rolling machines.

9. Railroad and Transportation: Plate rolling machines are utilized to create bended parts for rail line vehicles, tram vehicles, and different transportation gear.

10. Custom Metalwork: Numerous custom metal manufacture projects, like models, work of art, and structural highlights, depend on plate rolling machines to accomplish exceptional bended shapes.

11. Energy Area: Plate rolling machines assume a part in assembling parts for environmentally friendly power frameworks like breeze turbines and sunlight based charger upholds.

12. Assembling of Transports and Material Taking care of Hardware: These machines are utilized to make bended transport lines and other material dealing with gear in assembling and dispersion offices.

13. Mining and Material Handling: Plate rolling machines can deliver bended parts for mining gear and material handling machinery.

14. Horticultural Hardware: The rural area uses plate rolling machines to make bended metal parts for machinery like furrows and harrows.

15. Food Handling: In the food business, plate rolling machines can be utilized to fabricate bended parts for handling hardware and transports.

FAQ:

Q. What is a plate rolling machine?

Ans: A plate rolling machine is a modern machine used to twist or fold level metal plates or sheets into bended or round and hollow shapes. It comprises of three rollers, with the top and base rollers giving the bowing power and the center roller changing the ideal bend.

Q. What materials can be moved utilizing a plate rolling machine?

Ans: Plate rolling machines are essentially utilized for rolling metals, like steel, tempered steel, aluminum, and other compounds. The particular material that can be rolled relies upon the machine's ability and the kind of rollers utilized.

Q. What are the fundamental parts of a plate rolling machine?

Ans: The principal parts of a plate rolling machine incorporate the casing, rollers (top, base, and center), water powered or mechanical frameworks for changing the rollers, and controls for working the machine.

Q. What kinds of shapes can be created with a plate rolling machine?

Ans: Plate rolling machines can deliver various shapes, including chambers, cones, and portions of bigger circles. The reachable shape relies upon the machine's ability and the administrator's expertise.

Q. What are the various sorts of plate rolling machines accessible?

Ans: There are three primary kinds of plate rolling machines: pyramid-type (starting squeeze), three-roll (twofold squeeze), and four-roll machines. Each type enjoys its own benefits and is fit to various applications.

Q. What is the distinction between introductory squeeze and twofold squeeze plate rolling machines?

Ans: Starting squeeze machines have the top and base rolls fixed ready, requiring the administrator to make different passes to accomplish the ideal ebb and flow. Twofold squeeze machines have both the top and base rolls customizable, taking into consideration single-pass rolling and further developed precision.

Q. What is the advantage of utilizing a CNC-controlled plate rolling machine?

Ans: CNC (PC Mathematical Control) plate rolling machines offer accuracy and robotization. They consider programmable control of the twisting system, bringing about reliable and precise bended shapes. CNC machines are great for mind boggling and high-volume creation.

Q. What wellbeing safeguards ought to be taken while utilizing a plate rolling machine?

Ans: Security insurances incorporate wearing fitting individual defensive gear (PPE), guaranteeing the machine is appropriately kept up with, utilizing watchmen and wellbeing gadgets, and keeping maker's rules and wellbeing systems. Administrators ought to likewise get preparing on safe machine activity.

Q. Will plate rolling machines handle thick plates?

Ans: Plate rolling machines come in different sizes and limits. A few rock solid machines can deal with thick plates, while more modest machines are intended for more slender materials. It's fundamental to pick a machine that matches the thickness of the plates you want to roll.

Q. What support is expected for a plate rolling machine?

Ans: Standard upkeep incorporates grease of moving parts, examination of water driven frameworks, and checking for mileage on rollers and different parts. Follow the producer's support timetable and rules for ideal execution and wellbeing.

Q. How might I decide the limit I really want for a plate rolling machine?

Ans: To decide the machine limit you really want, consider factors like the thickness and width of the plates you'll roll, as well as the ideal ebb and flow. Talk with a machine provider or maker for direction in view of your particular prerequisites.

Q. Are plate rolling machines flexible for different ventures?

Ans: Indeed, plate rolling machines are adaptable and track down applications in businesses like metal creation, development, aviation, auto, and the sky is the limit from there. Their capacity to make bended parts from level sheets of metal makes them significant in different assembling areas.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email