An ISO 9001:2008 Certified Company

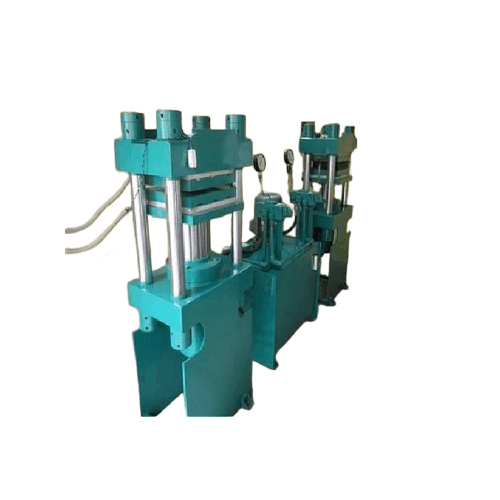

Hydraulic Rubber Moulding Press Machine

Product Details:

- Nominal Force 200 Ton

- Usage Hydraulic Rubber Moulding Press Machine

- Power Source Hydraulic

- Condition New

- Dimension (L*W*H) 1850 mm x 1250 mm x 2200 mm

- Product Type Hydraulic Rubber Moulding Press Machine

- Power(W) 15 kW

- Click to View more

X

Hydraulic Rubber Moulding Press Machine Price And Quantity

- 1 Piece

Hydraulic Rubber Moulding Press Machine Product Specifications

- 1850 mm x 1250 mm x 2200 mm

- Blue

- 600 mm x 600 mm

- 380/415 V

- Hydraulic Rubber Moulding Press Machine

- Yes

- New

- Yes

- Available

- 200 Ton

- Heavy Duty Electric Motor

- Hydraulic Rubber Moulding Press Machine

- 400 mm

- 15 kW

- Yes

- Yes

- Hydraulic

Hydraulic Rubber Moulding Press Machine Trade Information

- Mumbai

- Western Union, Paypal

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Western Europe, Australia, Central America, North America, Middle East, Eastern Europe, South America, Asia, Africa

- All India

- ISO

Product Description

Hydraulic Rubber Moulding Press Machine

Advanced Moulding Precision

Benefit from exceptional molding accuracy using the four-pillar frame and high-grade steel heating plates. The precise temperature controlup to 350Censures consistently high-quality results for rubber sheet, gasket, and automotive component manufacturing.

Robust Construction and Safety

Built to last, the machine features a heavy-duty electric motor and a sturdy structure weighing approximately 2500 kg. Enhanced safety is delivered through emergency stop functionality, overload protection, and a comprehensive control panel, ensuring user and equipment security during intensive operations.

Versatile and Efficient Operation

Operators can easily switch between automatic and manual modes for mould ejection, maximizing flexibility. The user-friendly touchscreen or manual control panel, combined with a rapid 30-second cycle time, improves productivity while ensuring operational convenience and adaptability.

FAQs of Hydraulic Rubber Moulding Press Machine:

Q: How does the four-pillar frame design enhance the performance of the hydraulic rubber moulding press machine?

A: The four-pillar frame ensures high structural stability and uniform pressure distribution, which results in improved accuracy during rubber molding. This robust design enhances durability and maintains precise alignment during each press cycle.Q: What are the main applications of this hydraulic rubber moulding press machine in industry?

A: This machine is primarily used for manufacturing rubber sheets, gaskets, and various automotive rubber parts. Its precision and high nominal force make it ideal for demanding industrial sectors that require consistent and high-quality rubber products.Q: When should the high-grade steel heating plate temperature be set up to 350C?

A: The heating plate should be set to the required temperatureup to 350Cbased on the specifications of the rubber compound and the molding process. Proper temperature ensures optimal material flow and curing during production.Q: Where can this hydraulic rubber moulding press machine be installed and used?

A: This press is suitable for installation in industrial production facilities, such as rubber manufacturing plants, automotive parts factories, and gasket production units. It is widely supplied and exported from India to various sectors globally.Q: What is the process for mould ejection on this machine?

A: The machine offers both automatic and manual mould ejection options. After the molding cycle, operators can choose to eject moulded parts automatically for speed and efficiency or manually when more control is needed.Q: How do the safety features enhance the benefit of using this moulding press machine?

A: Safety features such as the emergency stop button and overload protection safeguard operators and the equipment. These mechanisms quickly halt operations in hazardous situations and prevent mechanical or electrical overload, minimizing downtime and ensuring a safe workspace.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email