An ISO 9001:2008 Certified Company

Hydraulic Baling Press Machine Exporters In Maharashtra

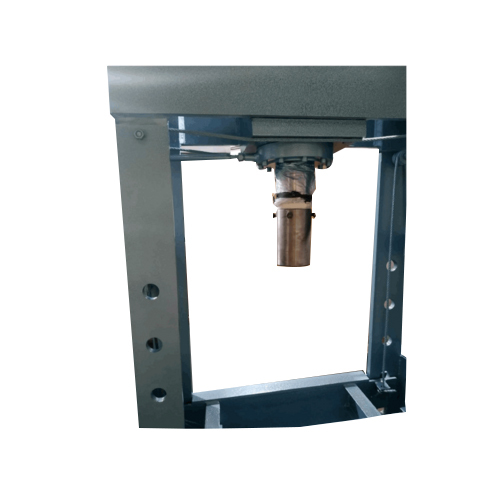

Product Details:

- Nominal Force 100 Ton

- Power Source Hydraulic

- Condition New

- Dimension (L*W*H) 2260 mm x 1100 mm x 2850 mm

- Power(W) 7.5 kW

- Voltage 380 V

- Motor Heavy Duty Electric Motor

- Click to View more

X

Hydraulic Baling Press Machine Exporters In Maharashtra Price And Quantity

- 1 Piece

Hydraulic Baling Press Machine Exporters In Maharashtra Product Specifications

- Yes

- 380 V

- Heavy Duty Electric Motor

- 100 Ton

- 1200 mm

- Integrated

- Yes

- Hydraulic

- New

- 1000 mm x 800 mm

- 2260 mm x 1100 mm x 2850 mm

- Available

- Yes

- 7.5 kW

Hydraulic Baling Press Machine Exporters In Maharashtra Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- All India

- CE & ISO

Product Description

We are manufacturer, Supplier and exporter of Scrap Baling Press. Our Scrap Baling Machine that is highly automated and simple in operation with single compact unit mounted over the channel. Fabricated in compliance with set International quality standards,Efficient Scrap Compression

Our Hydraulic Baling Press Machines are engineered for rapid and consistent compression of various industrial scrap materials. The machines deliver high-pressure operation through integrated proportional, pre-fill, and solenoid valves, optimizing the baling process for metal, plastic, cardboard, and paper. With a cycle time of just 40 seconds, users experience swift turnaround and improved productivity in waste handling environments.

Advanced Automation and Safety

Equipped with a fully automated electrical panel and PLC system, these semi-automatic baling presses ensure safe and easy operation. The built-in pressure gauge and heavy-duty construction provide reliability while protecting operators and maintaining quality standards. The system is devised to minimize manual intervention while ensuring accurate monitoring and control during each cycle.

Versatility for Industrial Applications

Suitable for industrial environments, the machine efficiently compresses a wide range of materials, including metal scraps, plastics, paper, and cardboard. Its large working table and maximum opening distance support bulk handling and large pieces, making it ideal for manufacturers, recyclers, and scrap exporters seeking enhanced bale consistency and space-saving solutions.

FAQ's of Hydraulic Baling Press Machine Exporters In Maharashtra:

Q: How does the hydraulic baling press machine enhance industrial scrap management?

A: The machine compresses scrap materials such as metal, plastic, cardboard, and paper into compact bales, simplifying storage, handling, and transportation for industrial recycling processes. This leads to optimized space utilization and improved logistics.Q: What is the typical process for using this hydraulic baling press in an industrial setting?

A: Operators load the scrap material onto the working table, initiate the cycle via the automated control panel, and the machine applies a nominal force up to 100 tons over a 40-second cycle. Compressed bales can then be easily removed and prepared for further handling.Q: When is this baling press most beneficial for manufacturers or exporters?

A: This machine is most advantageous when large volumes of recyclable or scrap materials require compression, particularly in facilities aiming to reduce waste volume, improve recycling efficiency, or prepare scrap for export.Q: Where can these hydraulic baling press machines be installed?

A: They are ideally installed in industrial scrap yards, recycling centers, manufacturing plants, and export facilities across India where frequent and high-output baling processes are required.Q: What are the key benefits of the integrated PLC system and control panel?

A: The PLC system and automated control panel deliver precise control, enhance safety, reduce manual intervention, and support consistent bale quality, thereby improving operational reliability and efficiency.Q: Can this baling press handle different materials, and how efficient is the cycle time?

A: Yes, the machine effectively compresses metal, plastics, cardboard, and paper. Its 40-second cycle time ensures quick processing, maximizing throughput during continuous operations.Q: What maintenance is required for optimal performance of the hydraulic baling press?

A: Regular inspection and servicing of hydraulic components, oil levels, valves, and the pressure gauge are recommended to maintain consistent pressure, extend machine life, and ensure safe operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email