An ISO 9001:2008 Certified Company

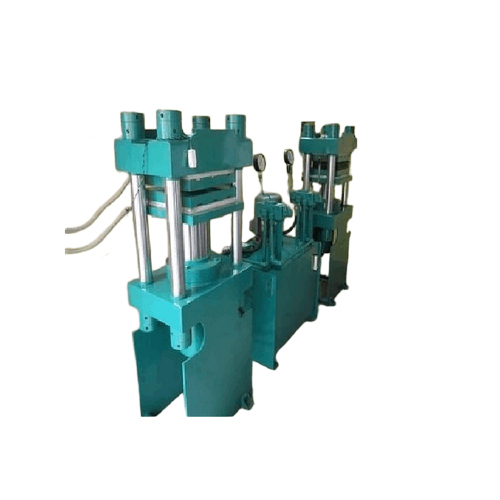

100 TON hand operated hydraulic press

165000 INR/Number

Product Details:

- Nominal Force 100 TON

- Power Source Manual / Hydraulic

- Condition Brand New

- Dimension (L*W*H) Approx. 1800 mm x 800 mm x 2200 mm

- Power(W) Hand Operated (No Electric Power Required)

- Motor Not Required (Hand Pump Operation)

- PLC System Not Included (Manual Operation)

- Click to View more

X

100 TON hand operated hydraulic press Price And Quantity

- 1 Number

- 165000 INR/Number

100 TON hand operated hydraulic press Product Specifications

- Manual / Hydraulic

- Included

- 100 TON

- Approx. 700 mm x 500 mm

- Brand New

- Approx. 1800 mm x 800 mm x 2200 mm

- Not Included

- Hand Operated (No Electric Power Required)

- Not Included (Manual Operation)

- Approx. 800 mm

- Not Required (Hand Pump Operation)

- Included

100 TON hand operated hydraulic press Trade Information

- MUMBAI PORT

- Telegraphic Transfer (T/T)

- 30 Days

- If order is confirmed we will reimburse the sample cost

- WOODEN BOX

- Asia

- All India

- ISO9001:2015

Product Description

Introducing our New, Popular, and Scarce 100 TON hand operated hydraulic press, designed for first-class performance in demanding industrial environments. Featuring a heavy-duty welded steel frame and a ravishing industrial-grade paint finish, this press delivers enviable versatility for bending, forming, punching, straightening, assembly, and disassembly tasks. Enjoy a maximum ram stroke of 400 mm, a robust 220 mm cylinder bore, precise hand lever operation, and enhanced safety with a pressure relief valve. Equipped with V-blocks, table plates, and a pressure gauge, this brand new press is ideal for exporters, manufacturers, and suppliers seeking reliable, electricity-free operations across India.

Direction of Use & Application Surface Areas

The 100 TON hand operated hydraulic press is straightforward to operate with its manual hand pump and hand lever system. Position your workpiece on the robust working table, ensuring it rests on the provided V-blocks or table plates. Suitable for flat and even industrial application surfaces, this press excels in metal bending, forming, straightening, punching, and assembly or disassembly tasks across workshops and manufacturing setups. Carefully align materials, engage the hand lever, and control the process with the integrated pressure gauge for optimal results.

FOB Port, Main Domestic Market & Packaging Details

The proposal amount for each unit of the 100 TON hand operated hydraulic press is confirmed upon order placement. Orders are handed over for shipping at your preferred FOB port in India with secure and robust packaging to safeguard against transit damage. Freight can be arranged as per client instructions, ensuring efficient and reliable delivery to the main domestic market across major Indian cities. All presses are shipped with accessories such as V-blocks and table plates, ready for immediate industrial use.

Direction of Use & Application Surface Areas

The 100 TON hand operated hydraulic press is straightforward to operate with its manual hand pump and hand lever system. Position your workpiece on the robust working table, ensuring it rests on the provided V-blocks or table plates. Suitable for flat and even industrial application surfaces, this press excels in metal bending, forming, straightening, punching, and assembly or disassembly tasks across workshops and manufacturing setups. Carefully align materials, engage the hand lever, and control the process with the integrated pressure gauge for optimal results.

FOB Port, Main Domestic Market & Packaging Details

The proposal amount for each unit of the 100 TON hand operated hydraulic press is confirmed upon order placement. Orders are handed over for shipping at your preferred FOB port in India with secure and robust packaging to safeguard against transit damage. Freight can be arranged as per client instructions, ensuring efficient and reliable delivery to the main domestic market across major Indian cities. All presses are shipped with accessories such as V-blocks and table plates, ready for immediate industrial use.

FAQs of 100 TON hand operated hydraulic press:

Q: How is the 100 TON hand operated hydraulic press operated?

A: The press is manually operated using a hand lever and a robust hand pump system, making it easy to control pressure and movement without the need for electrical power.Q: What safety features are included in the hydraulic press?

A: A pressure relief valve is incorporated to prevent overloading, and a pressure gauge is provided for precise monitoring, ensuring safe operation during all forming and bending activities.Q: Where can the 100 TON hydraulic press be used effectively?

A: It is ideally suited for workshops, manufacturing plants, metal fabrication facilities, and other industrial environments where heavy-duty bending, straightening, assembly, or disassembly is required.Q: What types of applications is this hydraulic press suitable for?

A: This press can be used for metal bending, forming, punching, straightening, assembly, and disassembly, making it a valuable asset in diverse fabrication and maintenance operations.Q: When should I use the V-blocks and table plates?

A: V-blocks and table plates are recommended for securely positioning workpieces during pressing tasks, ensuring stability and accuracy when performing forming, punching, or straightening operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email