An ISO 9001:2008 Certified Company

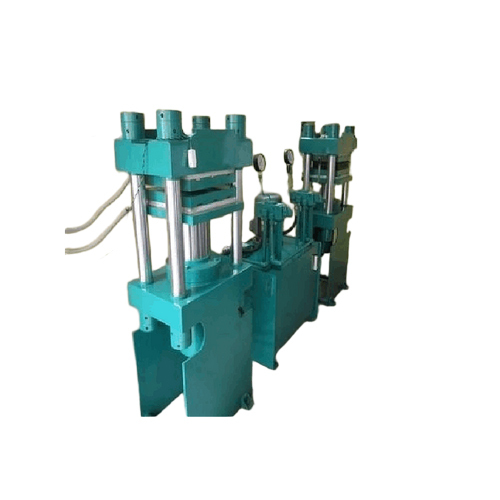

Hydraulic Rubber Moulding Press Machine Manufacturers Mumbai

Product Details:

- Nominal Force 100-500 Ton

- Power Source Electric

- Condition New

- Dimension (L*W*H) 2000 mm x 1200 mm x 1800 mm

- Power(W) 5 kW

- Voltage 220-440 V

- Motor 380V/50Hz/3Phase

- Click to View more

X

Hydraulic Rubber Moulding Press Machine Manufacturers Mumbai Price And Quantity

- 1 Piece

Hydraulic Rubber Moulding Press Machine Manufacturers Mumbai Product Specifications

- 220-440 V

- 600 mm x 600 mm

- 5 kW

- 380V/50Hz/3Phase

- Fitted

- Present

- Electric

- 2000 mm x 1200 mm x 1800 mm

- 100-500 Ton

- Fitted

- Included

- New

- Available

- 400 mm

Hydraulic Rubber Moulding Press Machine Manufacturers Mumbai Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Australia, Africa

- All India

- CE & ISO

Product Description

We Are Offering Rubber Moulding Press That is Designed With Automatic Closing Mould and Curing Calculate Time. Our Offered Moulding Press Finds Application in Various Types of Industries, Which Are Involved in the Process of Rubber Molding.Advanced Frame Design for Stability and Strength

With options for an H-Frame or 4-Pillar construction, this press ensures rock-solid stability even under extreme operating conditions. The rugged frame design, combined with a fixed bed type and robust painted, rust-proof finish, delivers high durability-making it ideal for the demands of continuous industrial rubber moulding.

Precision Control with Advanced Automation

Equipped with a digital and manual control panel, along with a sophisticated PLC system, this moulding press ensures efficient, reliable operations. The combination of proportional, solenoid, and pre-fill valves allows seamless adaptation to various moulding tasks, while the short cycle time of around 30 seconds boosts overall productivity.

Safety and Efficiency for Modern Manufacturing

Operator safety is prioritized through the inclusion of emergency stop mechanisms and protective safety guards. The system's power-efficient 5 kW motor, oil tank capacity of 200 liters, and real-time pressure gauge monitoring ensure consistent, safe performance even during extended production runs.

FAQ's of Hydraulic Rubber Moulding Press Machine Manufacturers Mumbai:

Q: How does the dual daylight feature benefit the rubber moulding process?

A: The dual daylight design allows for simultaneous moulding of two sets of products or faster loading and unloading between cycles, increasing throughput and production efficiency in rubber product manufacturing.Q: What applications is the Hydraulic Rubber Moulding Press suitable for?

A: This machine is ideal for manufacturing rubber components such as gaskets, mats, and O-rings. Its adjustable operating temperature and high nominal force make it suitable for demanding industrial and automotive sealing product applications.Q: Where can the Hydraulic Rubber Moulding Press machine be installed?

A: As a compact and robust machine, it fits well in industrial environments such as rubber manufacturing plants, automotive component workshops, and material test laboratories requiring consistent rubber moulding output.Q: What are the primary safety features provided with this hydraulic press?

A: Operator safety is enhanced by emergency stop buttons, durable safety guards, and clear digital/manual controls, ensuring secure handling during every stage of operation.Q: How does the PLC system improve automation in the press operation?

A: The integrated PLC system streamlines and automates production cycles, allowing precise control over parameters such as time, pressure, and temperature while enabling quick adjustments for different moulding requirements.Q: When is it advisable to use automatic versus semi-automatic modes?

A: Automatic mode is ideal for high-volume, repetitive moulding tasks where reduced manual intervention is preferred, while semi-automatic mode allows for greater operator input during prototyping or small-batch production.Q: What is the maintenance process and how does the fixed bed design help?

A: Routine maintenance involves checking the oil tank, valves, and cleaning the surfaces. The fixed bed design minimizes moving parts, reducing wear and simplifying both maintenance and part replacement downstream.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email