An ISO 9001:2008 Certified Company

Hydraulic Plate Rolling Machine Manufacturer Supplier from India

Product Details:

- Drive Hydraulic Motor Drive

- Cooling System Oil Cooling (Hydraulic)

- Noise Level < 75 dB

- Lubricating System Automatic Lubrication

- Motor Power 15 kW

- Machine Type Hydraulic Plate Bending/Rolling

- Production Capacity Up to 10 meters/min sheet rolling

- Click to View more

X

Hydraulic Plate Rolling Machine Manufacturer Supplier from India Price And Quantity

- 1 Piece

Hydraulic Plate Rolling Machine Manufacturer Supplier from India Product Specifications

- 15-25 HP (as per model)

- Manual/Automatic

- Hydraulic Plate Rolling Machine

- 11-18.5 kW

- 50 Hz

- 415 V

- Heavy Duty Steel Fabricated Frame, High Precision Rollers, Overload Protection

- Customized (example: 4200 x 1800 x 1600 mm)

- Optional Remote Control

- HPB Series

- PLC or Push Button Control

- Paint Coated

- 5C 45C

- 0.25 mm

- 4000-12000 kg (model specific)

- Hydraulic Driven

- Automatic Lubrication

- 15 kW

- Up to 320 Ton

- Welded/Robust Frame

- Sheet Metal Forming, Bending MS/SS/Aluminium Plates

- Hydraulic Plate Bending/Rolling

- Up to 10 meters/min sheet rolling

- Hydraulic

- Blue/Grey

- < 75 dB

- Oil Cooling (Hydraulic)

- Hydraulic Motor Drive

Hydraulic Plate Rolling Machine Manufacturer Supplier from India Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- CE & ISO

Product Description

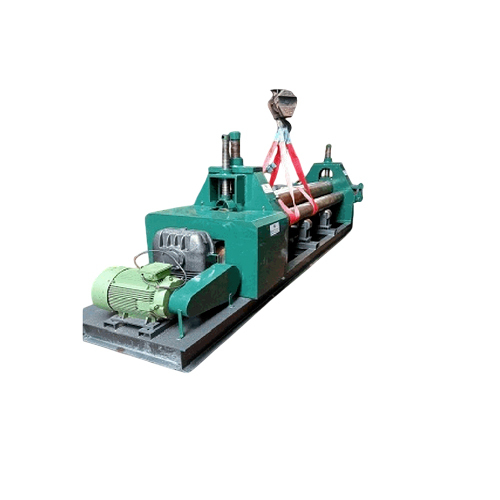

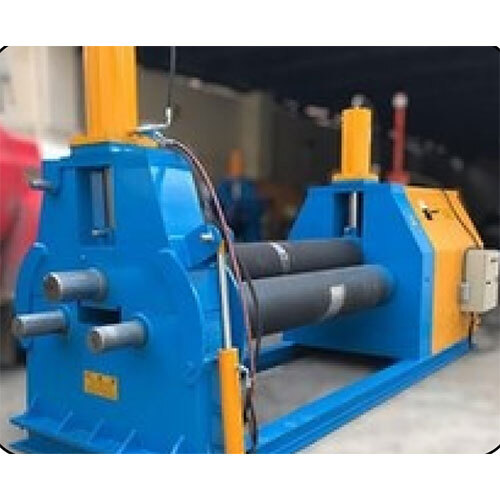

We Offer a Wide Array of Excellent Quality 3 Roll Hydraulic Plate Bending Machine. Manufacturer and Supplier of Hydraulic Plate Bending Machine From Mumbai, India.

1. Performance

2. Reliability

3. Quality

4. Technology

5. Experience

6. Service

Precision Plate Rolling Made Easy

Our hydraulic plate rolling machines combine robust construction, high precision rollers, and advanced hydraulic technology to deliver exceptional bending results for metal sheets. Custom dimensions and multiple models enable solutions for diverse fabrication needs, ensuring production capacities up to 10 meters per minute with consistent accuracy.

Advanced Features for Operator Safety and Efficiency

Designed with a heavy-duty welded frame, automatic lubrication, overload protection, and user-friendly operator panels, these machines are as safe as they are efficient. Integrated safety systems-including emergency stop buttons and limit switches-provide peace of mind, while hydraulic motorized adjustments deliver seamless operation.

Comprehensive Service and Support

We offer onsite installation and hands-on training to ensure seamless integration and optimal performance. Optional accessories such as conical bending attachments, digital readouts, and NC controllers further enhance machine capability, while CE/ISO compliance guarantees international standards.

FAQ's of Hydraulic Plate Rolling Machine Manufacturer Supplier from India:

Q: How does the hydraulic plate rolling machine improve sheet metal forming efficiency?

A: The hydraulic technology provides precise control of roll adjustment and pressure, enabling consistent and accurate plate bending. With production speeds up to 10 meters/min, operators can streamline sheet metal forming for MS, SS, and aluminium plates with minimal downtime.Q: What materials and thicknesses can be processed on these machines?

A: Our machines handle a wide range of materials including mild steel, stainless steel, and aluminium. They support rolling plate thicknesses from 1 mm to 25 mm and widths between 2500 mm and 4000 mm, depending on the selected model.Q: Where are these machines manufactured and exported from?

A: All hydraulic plate rolling machines are manufactured, supplied, and exported directly from our facility in India, adhering to CE and ISO certifications for assured quality.Q: What is the process for installing and commissioning the equipment?

A: We offer onsite installation and training, ensuring that customers are fully equipped to operate the machine. Our team guides you through setup, safety procedures, and operational adjustments for optimal productivity.Q: What usage advantages does the machine's hydraulic-driven design offer?

A: Hydraulic-driven systems deliver smooth, powerful motion for both manual and automatic operation. The design features overload protection, high precision rollers, and heavy-duty frames for durable, reliable usage in demanding fabrication environments.Q: When should optional accessories like NC controller or conical bending attachment be considered?

A: Optional accessories can be selected during initial purchase or added later to expand machine capability. NC controllers enable advanced automation, while conical bending attachments facilitate specialized metal forming tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email